Missing parts, full warehouses, and complex demand structures:

Disposition often means reacting to deviations instead of managing proactively.

This is exactly where the AI-based business software ADD*ONE comes in – with transparency, automation, and reliable forecasts.

The solution suite bundles and analyzes your inventory and demand data for you. If desired, it takes over routine tasks and immediately highlights relevant actions that need to be taken – including optimal order suggestions. This means you know which items you should order, when, in what quantity, and from which supplier, and you are notified of any exceptions at an early stage. The system provides you with exactly the information that is relevant to your specific task. Precisely prepared. Clearly prioritized. Ready to use.

This allows you to manage your inventory proactively. Impending bottlenecks or schedule deviations remain manageable.

Workdays become plannable again. Shortages and excess inventory are reduced.

The result: 50% less planning effort. Maximum delivery capability. Minimal storage costs.

Your advantages

- Make confident decisions. Because forecasts are finally reliable.

- Work smart. Because routines no longer hold you back.

- Deliver reliably. Because availability becomes predictable.

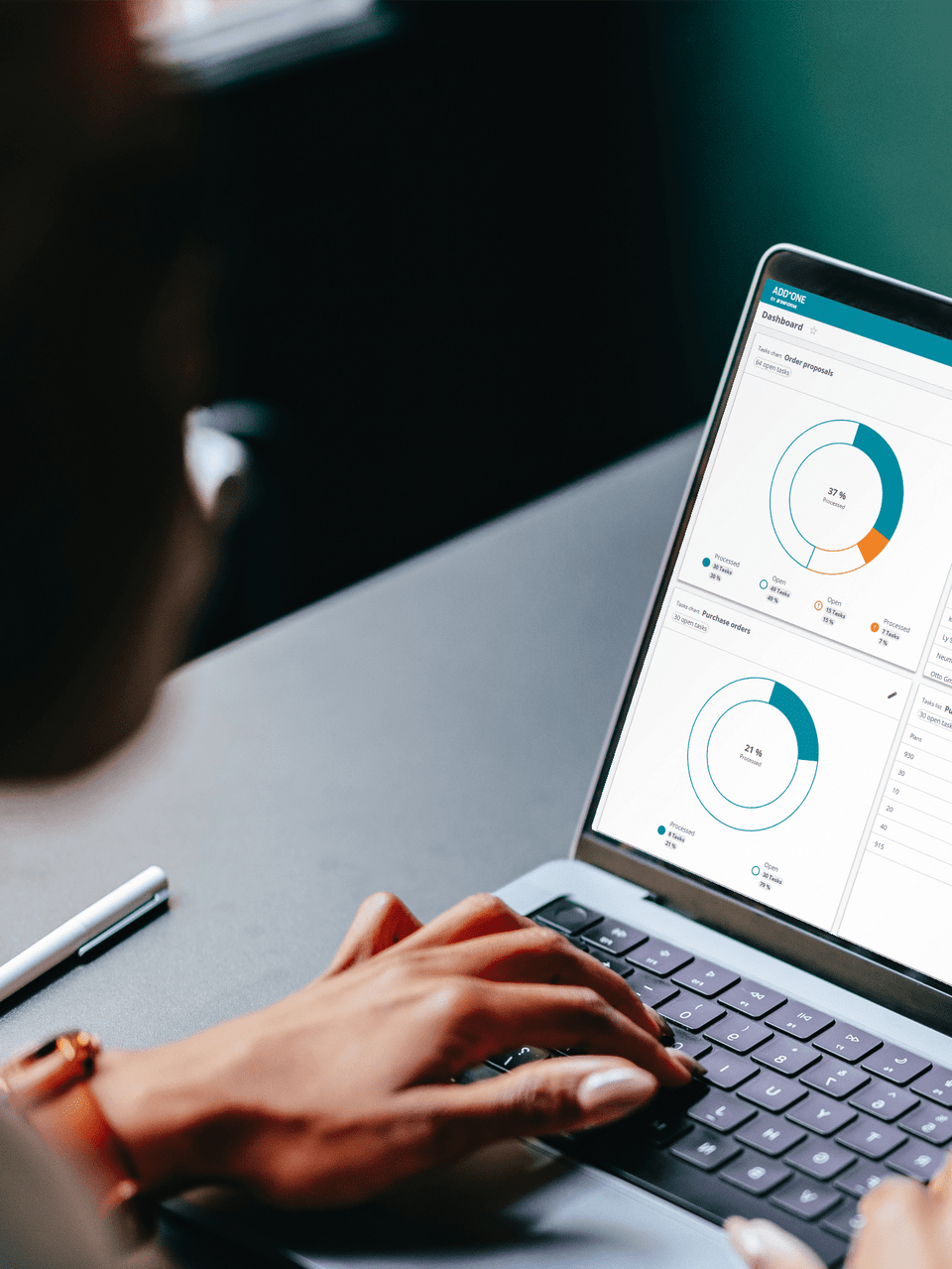

Personalized

With ADD*ONE Inventory Optimizer, you can work in a consistently task-oriented manner and keep an eye on your most important key figures at all times. Your personal dashboard clearly shows you which orders have already been placed and where specific action is required. In addition, you receive well-founded recommendations for action, for example regarding supplier selection. You can identify delivery delays, impending stockouts, and excess inventory at an early stage.

Intuitive

The intuitive dispography provides clear transparency regarding sales history, seasonality, and expected sales. You can plan flexibly on an annual, monthly, or daily basis and maintain an overview at all times, even with complex structures. Relevant key figures are clearly visualized and can be evaluated interactively—a reliable basis for quick and informed planning decisions.

Reliable

Clearly presented item forecasts provide a reliable basis for your decisions. Different forecasting models, including modern demand AI technology, deliver comprehensible forecasts and support forward-looking and resilient planning.

Inventory Optimization works on several levels

Decision-maker

Purchaser

IT

What companies say about inventory management with ADD*ONE

Before using the software, we only had all the important data in Excel spreadsheets. ADD*ONE, on the other hand, optimally presents the data graphically, such as the sales history of each individual item, but also the forecast demand and existing orders. This allows us to understand how the data is developing overall much more quickly and effectively.

Inventory reduced by 30 percent just six months after introduction

Transparency at all times regarding sales history, forecasted demand, and existing orders for all items

Work more efficiently with automated, cost-optimized order suggestions

Thanks to ADD*ONE's forecasts, order triggering is now more forward-looking. This has led to a reduction in the delivery frequency of frequently sold items, which are now ordered in larger quantities.

Increase in item availability to 97.5%

Higher delivery reliability

Bundled ordering processes and smoothing of demand peaks

ADD*ONE gives us the freedom to focus on the real challenges in our procurement. The combination of artificial intelligence for standard cases and human intelligence for special cases has proven to be a complete success.

Away from Reacting and toward Acting

"Management by exception" and automated ordering processes

Dynamic calculation of optimal safety stocks

Regarding the “management by exception” principle: This has not only led to a significant reduction in the workload for employees, but also to the elimination of a full-time position that we no longer had to fill, which is a major advantage in times of skilled labor shortages. In addition, the working environment for our employees has become noticeably more relaxed.

Savings in the millions thanks to reduced inventory

Automation of all standard orders

Greater safety thanks to simulations and reliable forecasts

Without the forecasting and demand planning in ADD*ONE, febi bilstein would be lost in its day-to-day business. The logistics key figures determined, such as inventory range and delivery readiness, make decision-making much easier for us.

Balanced inventory levels despite volatile demand thanks to accurate forecasts

Stable liquidity level despite massive expansion of product range

Simplified scheduling and high product availability thanks to automation

With ADD*ONE inventory optimization, we also ensure greater efficiency in production for our suppliers, as material orders can now be coordinated across countries and locations and transmitted to our suppliers.

Transparent Data and Planning across all International Locations

Reduction in Inventories

15% Increase in Productivity

Thanks to the excellent visualization in ADD*ONE, we can now see at a glance the initial situation of an article, its future development, and the urgent need for action.

Planning and scheduling at item level enables

20% fewer goods received with the same availability

100% of dispatchers confirm that their work has become easier

ADD*ONE helps us keep a close eye on our product range. After just a short time, the visual display gives you a good feel for how an item is performing.

Increase in service level to 97%

Planning reliability over a 12-month horizon

Greater efficiency and less stress in scheduling

In the past, it took us hours to make an informed decision. Today, we can perform complex queries on inventory levels, order histories, or sales figures at the touch of a button in a matter of seconds and obtain tangible insights immediately.

Increase in delivery capacity by over 10%

Development of an intelligent system for the automated selection of the best suppliers

Reduction in scheduling effort through reduced routine tasks

FAQ's

Why do I need inventory optimization software in addition to my ERP system?

Traditional ERP systems usually map inventory management and planning in a rule-based and static manner (example: reorder point method). Our solution, on the other hand, uses AI-based forecasting models to take into account seasonality, demand, fluctuations, promotions and external factors, and automatically generates optimised order proposals.

How is the inventory management software connected to our existing system landscape?

The inventory optimisation software is seamlessly connected to existing ERP and merchandise management systems via standard interfaces. Master data, inventories and transaction data are automatically synchronised.

This creates a consistent database for sales forecasting, scheduling and inventory optimisation without media breaks or manual data maintenance.

How long does it take to implement the inventory management and procurement software?

Implementation is structured and usually productive within a short period of time. Initial effects such as improved delivery capability, optimised inventories and more stable scheduling processes are usually measurable shortly after go-live.

How much internal effort is required for inventory management and scheduling after implementation?

After implementation, the inventory management software works largely automatically. Schedulers receive specific order and scheduling suggestions instead of having to manually calculate sales forecasts and safety stocks.

The ongoing effort in operational inventory management is significantly reduced, while planning reliability and transparency increase.

What specific measurable benefits does the inventory management software offer?

The solution reduces excess inventory, improves delivery capacity and lowers capital commitment through precise, AI-supported sales forecasts and automated order proposals.

At the same time, the manual planning effort is significantly reduced, as planners work with clear recommendations for action instead of time-consuming analyses.

The result is stable processes, lower costs and greater planning reliability.

How does the solution support operational procurement and planning?

The inventory management software generates automatic demand and order proposals based on precise sales forecasts. Delivery times, minimum order quantities and inventory targets are systematically taken into account.

This makes scheduling more predictable, faster and significantly less prone to errors.

How does inventory optimization work across multiple warehouses or branches?

The software enables cross-location inventory management and takes into account multiple warehouses, branches or distribution centres simultaneously.

Network-wide planning ensures that inventories are optimally distributed, stock transfers are sensibly controlled and delivery bottlenecks are avoided throughout the entire network.

How much does inventory optimisation software cost?

The cost of inventory management software depends on the range of functions, the number of items, the number of users using the system simultaneously and the integration requirements.

Flexible licence and subscription models ensure that the investment quickly pays for itself through optimised inventories, lower capital commitment and more efficient procurement.