May 13, 2025 Zdravka Ley

ShareIn modern production and logistics environments, every second counts. Whether tugger trains, forklifts, autonomous vehicles or material and transport containers, anyone who wants to efficiently control internal transport needs transparency in real time.

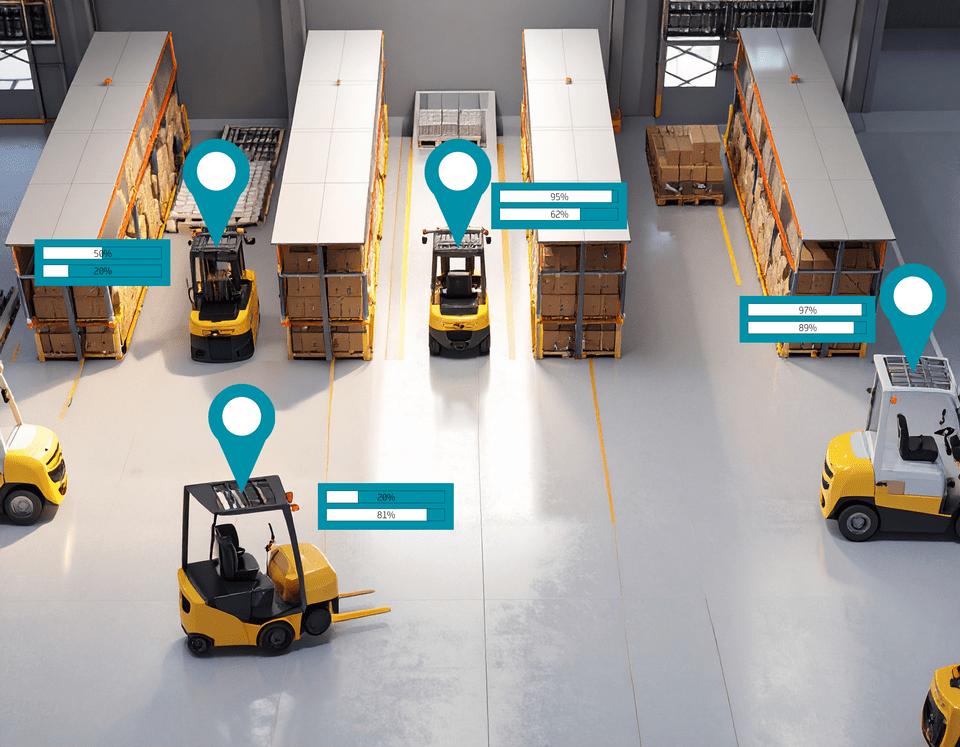

Real-time locating systems (RTLS) are increasingly being used to visualize the locations of vehicles, load carriers or containers within the plant in real time. If this precise location data is combined with intelligent transport logic, intralogistics can reach a new level of efficiency, flexibility and responsiveness.

What is Real-Time Locating System (RTLS)?

RTLS (Real-Time Locating System) is a technology for locating objects and people in real time, usually within buildings or demarcated factory areas. In contrast to GPS, which mainly works outdoors, RTLS uses different technologies such as ultra-wideband (UWB), Bluetooth Low Energy, RFID or WLAN-based localisation, depending on the application scenario. AI-supported systems are also increasingly being used in combination with cameras to detect positions and movements in the room. LIDAR-based methods are also used, for example to recognise the surroundings of driverless transport vehicles or for precise navigation in confined production environments.

An RTLS usually consists of three components:

- Tags or transponders on vehicles or objects

- Sensors or anchor points in space for determining position

- Software for evaluating and visualising the recorded data

In summary, RTLS technology visualizes the current location of an object and its movements. On this basis, logistics processes can be specifically analysed, improved and, in many cases, automated.

Where RTLS creates real added value: 4 application examples from logistics

The market for Real-Time Locating Systems (RTLS) has been experiencing dynamic growth for several years. According to the Real-Time Locating Systems Market Report 2025, the global market volume for RTLS is estimated at almost USD 15 billion in 2025. Analysts expect average annual growth of 29.8% until 2029 - to a total turnover of over USD 42 billion. This remarkable growth is due in particular to rising demand in areas such as manufacturing, logistics and supply chain management, retail inventory monitoring, employee safety and the increasing importance of patient care in the healthcare sector.

One of the driving sectors here is logistics. It symbolises the desire for greater transparency, efficiency and real-time automation. The concrete benefits of RTLS are particularly evident in intralogistics: when location data is intelligently integrated into existing processes, it opens up a wide range of optimization possibilities - from material flow and vehicle control to occupational safety.

- Vehicle localization in real time

RTLS enables the precise determination of the location of every forklift truck or tugger train - in real time and accurate to the metre. In addition to determining the position, operating data such as speed, abrupt braking manoeuvres or risky driving behaviour can also be recorded. This enables companies not only to track the use of their vehicles, but also to make it safer, more efficient and more transparent. - Container and load carrier tracking

RTLS makes it possible to locate pallets or other load carriers in real time - without any manual work steps such as scanning. This makes it possible to see at any time where which material is located, whether it is still in circulation or has already arrived at its destination. This reduces search times, avoids losses and increases stock accuracy in the long term. Scanning processes can be an enormous time waster, especially when handling several containers at the same time, for example during forklift transport with double or long forks, as barcodes are often not directly accessible to the driver. RTLS eliminates these manual activities and thus significantly speeds up the picking up and delivery of packages. - Support for driverless transport systems (AGV)

RTLS can not only supplement autonomous transport systems, but also actively support them for example with virtual guidelines, priority rules or defined stop zones. The systems receive precise positioning data for safe and efficient navigation. Especially in hybrid transport environments with people, forklift trucks and robots, RTLS facilitates coordination and enables smooth interaction between all parties involved. - Process safety & occupational safety

RTLS actively contributes to greater safety in the plant. Real-time monitoring allows access to restricted zones to be controlled, safety distances between vehicles to be maintained and critical situations such as risky driving manoeuvres to be detected. Automatic speed adjustments in hazardous areas are also possible. This provides digital support for occupational safety - preventively and in real time.

RTLS meets intelligent Intralogistics Management system

The combination of real-time location and intelligent transport control is the key to future-proof intralogistics. RTLS makes it possible to see where vehicles, containers or materials are located in real time and with centimetre precision. An intelligent intralogistics management system such as SYNCROTESS uses this information to derive specific actions, from triggering individual transports to dynamic route adjustments.

The benefits are particularly clear in hybrid fleets in which autonomous and manned vehicles are used in parallel. This is because these fleets are often controlled separately via their own systems, with separate data flows and limited transparency. This is precisely where SYNCROTESS comes in as a central management system for all resources and transport operations. It controls hybrid fleets of autonomous and manned vehicles intelligently and integrated in one solution.

SYNCROTESS processes RTLS data in order to:

- Assign transport orders dynamically and based on location

- Optimize tours and route trains in real time

- Immediately reschedule disruptions or delays

- Process-based consideration of security zones and access points

The integration of RTLS data into SYNCROTESS Intralogistics Management System not only provides real-time transparency, but also enables predictive, flexible control of internal transport operations - adapted to the specific requirements of ongoing operations.

Conclusion: Real-time data as the foundation of modern intralogistics

RTLS technologies make movements in the factory visible, SYNCROTESS makes them controllable. The combination of real-time localization and intelligent transport logic enables a new quality in internal logistics: more transparent, more flexible and safer.

If you want to control transport dynamically, utilize resources efficiently and react immediately to changes in operations, you need more than just data. They need a system that turns it into decisions. The integration of RTLS and SYNCROTESS is exactly that, a future-proof building block for digitally networked intralogistics.

Which processes in your intralogistics would benefit from more transparency and intelligent control?

About our Expert

Zdravka Ley

Marketing Manager

Zdravka Ley started working for INFORM in 2002 and is focused in topics around the optimization and sustainability of delivery and internal transport logistics.