Sustainable Development Goal (SDG) number 8 "Decent Work and Economic Growth" of the UN Sustainable Development Goals comprises two resolutions that may sound contradictory in view of many working conditions worldwide. An example of the optimization of yard management in companies illustrates how software can promote economic efficiency and better working conditions at the same time.

GROWTH LIMITS

All work should be carried out under humane conditions and be valuable for both the employee and the employer. However, not all people benefit fairly from the wealth generated by their work.

Sustainable economic growth should therefore counteract the disbalance between growth and fair pay and should not be achieved at the expense of the environment. SDG number 8 therefore also calls for a global improvement in the use of resources in production and consumption and aims to decouple economic growth from environmental degradation.

In biological terms, growth means a natural increase in the size of a living organism. The term is also defined in a figurative sense as an increase, rise or increase in something. Growth requires preconditions and resources and always assumes their availability. However, resources - raw materials, space, skilled workers - are becoming increasingly rare. As early as 1972, the Club of Rome predicted in its study "The Limits to Growth" that the absolute limits to growth on earth would be reached within the next hundred years and called for sustainable development.

An important and effective instrument for achieving sustainable growth is the digitalization of industry. Intelligent planning and control systems have been proving for many years that they can combine corporate goals such as profitability, efficiency, resource conservation and a healthy working environment. For example, in logistics and the organization of the arrival and departure of many trucks in a yard.

YARD MANAGEMENT SOFTWARE – TWO GOALS IN HARMONY

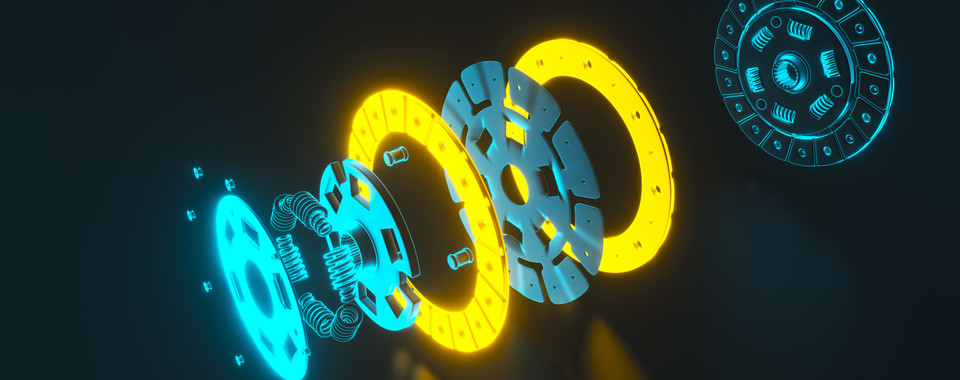

A yard management system is a good example of how growth and better working conditions can be supported sustainably in the company in equal measure. Yard management covers the logistics on the factory premises - the processes in front of and at the gate, from the loading dock to the exit - and is the link between delivery, warehouse and production logistics. If things come to a standstill in the yard, the effects can be felt in production, in the warehouse and all the way to the end consumer.

By digitizing and optimizing yard management, processes on the factory premises can be planned with dock appointment scheduling and organized with supply control. The aim is not only to utilize employees and resources more evenly and avoid stressful situations, but also to reduce waiting and throughput times for truck drivers. The yard management software takes driving and rest times into account and avoids unnecessary re-parking and maneuvering in the yard. This means that the increasing number of incoming trucks can be handled effectively with the available resources.

The digitalization and optimization of the yard thus leads to higher productivity, reduces the yard's CO2 footprint and supports compliance with health and safety conditions. Everyone involved benefits from the use of modern yard management systems through:

- Booking time slots with calculated lead times

- More even utilization of loading resources and plant employees

- Reduction of waiting and throughput times

- Consideration of driving and rest times as well as break times

- Clear real-time information, also on mobile devices

- Control of forklift trucks during loading and unloading

- Increase in safety standards.

TIME TO ACT

The logistics industry is repeatedly criticized. It is about rapidly rising transport rates and high profits for logistics companies, but also about poor working conditions and low wages. Politicians have already developed and implemented many concepts for the sustainable organization of truck traffic. Companies must now also work on making their logistics more sustainable. They do not have to choose between good working conditions and economic growth but can combine both intentions through digitalization. The example of optimizing yard management shows how economic, social and ecological aspects can be equally taken into account in decisions.