Sep 9, 2025 Mario Bock

ShareWithout them, comprehensive digitization strategies would be virtually inconceivable. Companies can use these virtual representations of real systems to monitor processes in real time, optimize workflows, and run through what-if scenarios without any risk. But what exactly is behind the buzzword “digital twin”?

What is a digital twin?

Digital twin refers to a virtual replica of a real object, process, or system that reflects its status and behavior based on real-time data. It enables the continuous monitoring, analysis, and optimization of processes and operations.

However, the exact definition of the term is not always consistent. Depending on the source, there are different definitions and gradations of what is considered a digital twin. The transitions between these gradations are often fluid.

Difference to digital shadow

A frequently used term is the digital shadow. Depending on the definition, this is either considered a refinement within digital twins or a preliminary stage. A digital shadow collects and visualizes data from the real world, but cannot actively use it to influence the physical object. It therefore serves only for passive monitoring and analysis.

A typical digital twin goes beyond this by not only receiving and analyzing data, but also actively influencing its real counterpart via bidirectional communication – for example, through direct control commands or automatically triggered measures.

Maturity levels and classification

Digital twins can also be classified according to different maturity levels that describe their functionalities, up to and including autonomous systems. While simple twins only visualize current states, more advanced models create diagnoses, forecasts, and recommendations for action.

The highest level of development is represented by fully autonomous digital twins, which make decisions independently, learn continuously, and optimize themselves. Supported by technologies such as machine learning and data mining, such autonomous systems could theoretically operate without human intervention and continuously improve processes independently.

Origins: From NASA to Industry 4.0

The idea of a digital twin dates back to the 1960s: During the Apollo moon missions, NASA used physical twin models to run through scenarios and solve problems (such as those encountered during Apollo 13) on the ground. However, these physical twins did not yet have real-time data connectivity and therefore did not correspond to today's understanding of a digital twin. As a formal concept in the modern sense, the digital twin was first introduced in 2002 by Dr. Michael Grieves (Florida Institute of Technology, NASA consultant), who outlined a virtual product model with continuous data connectivity to the real product. The name “digital twin” was then coined by John Vickers of NASA in 2010 as part of a technology roadmap, giving the concept an official name.

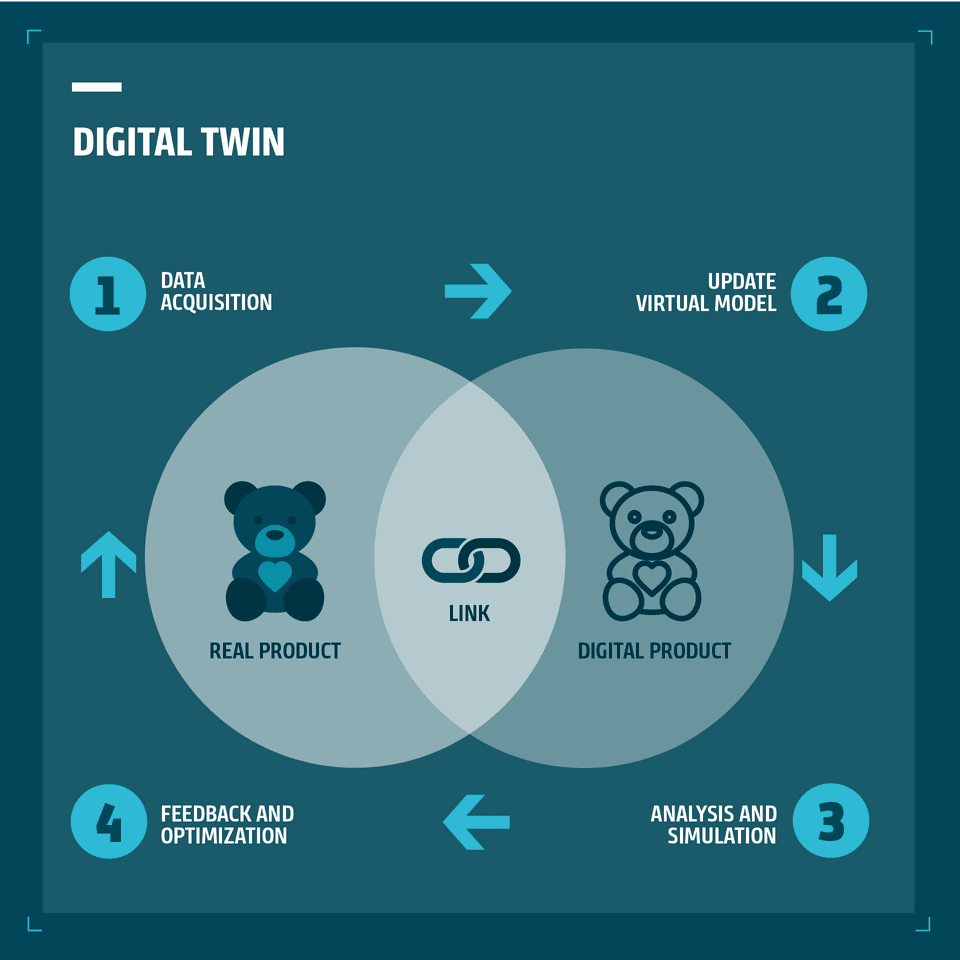

How does a digital twin work?

A digital twin links the physical and digital worlds through a constant flow of data. Its functionality can be explained in four simple steps:

- Data collection: Sensors on the real object (such as machines, vehicles, buildings, or even human organs) measure relevant parameters—e.g., temperature, position, speed, fill level, or vital signs. Existing systems, such as an ERP system, can also pass on current information, such as the movements of an item, to a digital twin.

- Updating the virtual model: The incoming sensor and operating data feed into a virtual model of the object. This model – the digital twin – contains all the information needed to realistically represent the current state. Changes in the physical object immediately lead to an update of the digital image (automatic synchronization). For example, if a robot arm in the factory increases its speed, the twin immediately reflects this new value.

- Analysis and simulation: In the digital twin, the data can be analyzed using algorithms. Data mining and machine learning play an important role here. In addition, what-if scenarios can be played out in the virtual model: How does a system react when the load increases? What happens in the event of a specific failure? Such simulations help to identify risks and bottlenecks, but also to identify optimization potential without having to interrupt real processes.

- Feedback and optimization: The insights gained can be used to derive measures. In simple cases, a human operator receives recommendations for action (e.g., bring forward maintenance, adjust parameters). In advanced scenarios, the digital twin sends control commands directly back to the physical system – this is referred to as a closed control loop. This allows the real object to respond to events in real time, controlled by its digital twin.

Application examples in various industries

A particularly illustrative area of application is container management. Load carriers such as containers, crates, or pallets are distributed over long distances and locations. Problems are therefore often only detected at a late stage. A container pool with several million assets, for example for transport in the retail sector (vegetables, meat, fish), is no exception. The complexity increases with the quantity and variety of containers, which makes transparency particularly relevant.

The digital twin of a load carrier not only reveals its current location and condition. Rather, it stores all the information necessary for efficient container management. For example, it can be stored which load carrier is allowed to transport which load, how many cycles it has already completed, when it was added to the pool, or where it was purchased. A digital twin thus provides the basis for intelligent, data-driven decisions.

We offer decision intelligence based on this, together with digital twins, in our SYNCROTESS software. This enables us to provide support in planning and control. We continuously analyze all available information automatically and derive recommendations for action: When do which and how many containers need to be where? How can short-term delays in the pool be compensated for? This decision support creates greater transparency across the entire container inventory, utilizes the existing container pool more efficiently, and reduces costs through shorter turnaround times.

Advantages and challenges

Digital twins offer a wide range of advantages, but also present some challenges. The following overview shows the most important aspects of both sides:

Vorteile

- Real-time monitoring and transparency: Continuous view of the condition and performance of systems or products. This improves the understanding of complex processes.

- Predictive maintenance: Early detection of malfunctions enables repairs before failures occur. This significantly reduces downtime and maintenance costs.

- Increased efficiency & cost savings: Optimized processes lead to higher productivity and lower resource consumption. Simulation can save time and money in development and operation.

- Decision support: The insights gained enable informed decisions to be made. “What-if” simulations provide a secure basis for weighing risks and driving innovation

Herausforderungen

- High data requirements: Large amounts of data must be collected, transmitted, and evaluated. Without reliable sensor technology and fast networks, seamless real-time synchronization is difficult.

- Integration and standardization problems: In heterogeneous environments, many systems and machines must be networked. Initiatives such as ISO 23247 help to overcome these hurdles by defining common reference models and interfaces.

- Data security and data protection: A twin collects extensive operating data. This sensitive information must be protected against cyberattacks and handled in accordance with data protection regulations.

- Acceptance and change management: The introduction of digital twins changes processes and often requires new expertise. Employees must be brought on board and trained. Sometimes there is reluctance, such as concerns about automation and job losses, which must be actively addressed.

Conclusion

As virtual counterparts of real systems, digital twins connect the physical and digital worlds and enable completely new insights into complex processes. Whether in production, logistics, energy, or medicine, the examples show that digital twins offer a wide range of advantages: processes become more efficient, failures less frequent, and innovations can be implemented more quickly. Changes can be tested and implemented immediately, and supported by data mining and machine learning, digital twins enable various optimization opportunities. As a result, digital twins have already become indispensable in many industries.

About our Expert

Mario Bock

AI Application Specialist | Corporate Marketing

Mario Bock has been working in Corporate Marketing at INFORM as an AI Application Specialist since 2023. He joined INFORM in 2016 and began his career in software development. Driven by his enthusiasm for artificial intelligence, he authored a book about the fundamentals of AI and now focuses on applying AI tools within marketing. With a passion for innovation and practical AI use cases, he helps shape the future of communication and content creation at INFORM.