Sep 4, 2025 Mario Bock

ShareProcess mining is a modern X-ray view of business processes. The technology objectively shows how business processes actually work, often revealing surprising insights and hidden optimization potential. Whether in manufacturing or customer service, process mining uncovers inefficient loops, bottlenecks, and deviations and helps to significantly improve processes.

What is Process Mining? (Definition)

Process mining is a method that uses digital traces from IT systems to automatically reconstruct and analyze business processes. Every action in a process leaves data traces in ERP, CRM, or workflow systems. Process mining tools combine these individual events and visualize the actual process flow holistically. This creates a data-driven model of the process that often looks different than expected. For example, it is possible to track how a customer order actually flows through different departments and where bottlenecks or delays occur. The well-founded view of actual processes bridges the gap between theoretical process models and reality. Instead of assumptions or idealized diagrams, process mining provides facts: Which steps are taken in which order, how long do they take, where do loops or waiting times occur? This enables companies to identify weaknesses at the touch of a button, compare processes, and substantiate their performance with key figures.

Background and Context

The foundations of process mining were laid as early as the late 1990s. Starting in 1998, computer scientist Wil van der Aalst (now a professor at RWTH Aachen University) researched methods for deriving processes from workflow log data. From research, process mining found its way into broad business practice in the 2010s.

With the success of the method, the number of available tools and specialized consulting firms also grew rapidly. The increasing availability, combined with the enormous added value, has led to process mining evolving from a niche approach to one of the most valuable tools for business process management and decision intelligence.

How does Process Mining work?

Process mining works by automatically collating and analyzing digital traces (event logs) from IT systems. Individual events such as timestamps, user actions, or transaction IDs are used to track individual objects through their processes and create a holistic view of real-world operations. Algorithms recognize typical patterns and sequences, visualize process steps, and thus enable an objective analysis of, for example, individual suitcases at the airport.

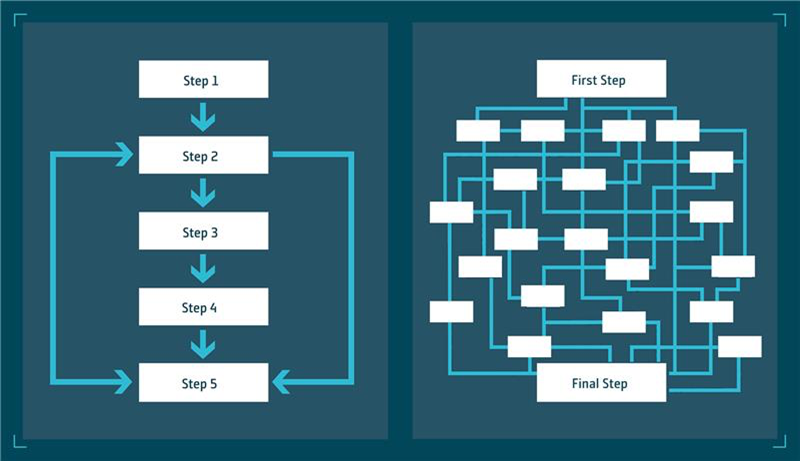

Many conventional process models often only map around 80% of all processes and rarely show where exactly delays occur, what intermediate steps there are, or what special cases occur. These simplified models are clear, but they do not reflect reality. A model that takes into account all real processes, including all exceptions, is often referred to as a “spaghetti model” because its complexity makes it seem almost impossible to understand at first glance.

Process mapping with and without process mining

This is where the integration of artificial intelligence (AI) comes in. AI helps to transform these initially confusing but realistic process models into precise, usable analyses. Machine learning algorithms automatically recognize relevant patterns within the complex data and enable deeper insights. These then enable improved forecasts and throughput times and create the basis for automated root cause analysis for bottlenecks. This creates digital twins of business processes from realistic process models – virtual representations that companies can use to perform targeted simulations, run through scenarios, and analyze optimization potential. This makes it possible not only to identify problems in the process, but also to fix them.

Application Examples

Process mining is now used across all industries, as virtually every field with digital processes can benefit from it. Especially in manufacturing, retail, banking, insurance, and healthcare, it helps to make complex processes such as production, loan applications, or claims settlement transparent and optimize them in a targeted manner.

Such optimizations are achieved, for example, by avoiding unnecessary process steps. Among other things, it is possible to analyze where tasks remain unprocessed for a particularly long time or which processes are repeated multiple times. A concrete example: A product is placed in storage during production, even though it is needed directly at the neighboring machine in the next step.

Advantages & Challenges

Process mining brings numerous advantages to companies, but also comes with practical challenges. An overview of the most important advantages and challenges:

Advantages

- Transparency: Process mining creates an objective, data-based view of processes. Instead of assumptions, you get clear facts about the actual process – including all variants and special cases.

- Increased efficiency: By identifying bottlenecks, loops, or media breaks, processes can be improved in a targeted manner. Companies discover potential savings in time and costs, as bottlenecks and unnecessary steps can be eliminated.

- Faster analysis: Automated algorithms can now sift through large amounts of event data in a short time. This eliminates the need for time-consuming manual interviews or workshop sessions to gather process information.

- Ensure compliance: Process mining reveals deviations from specified processes or guidelines. This helps to identify compliance violations at an early stage and ensure process quality and regulatory compliance (important, for example, in regulated industries).

- Continuous improvement: With regular data updates, process mining can serve as a monitoring tool. Processes can be continuously monitored, and improvement

Challenges

- Data quality and availability: The analyses are only as good as the underlying data. Missing timestamps, duplicate entries, or incomplete logs can distort results.

- Integration into the IT landscape: Processes usually run across multiple systems. To enable an end-to-end view, data sources must be merged and formats harmonized.

- Tool complexity and expertise: Setting up and using modern process mining software requires experience. Without trained users, there is a risk of drawing the wrong conclusions.

- Change management: Adjustments to existing processes are not always immediately accepted, so communication and employee involvement are crucial.

- Data protection and compliance: When analyzing employee activities, various requirements must be taken into account and, if necessary, measures such as anonymization must be applied.

FAQ About Process Mining

What distinguishes process mining from conventional process analysis?

Conventional process analysis usually relies on workshops, interviews, and manual modeling to describe target processes. Process mining, on the other hand, takes the opposite approach: it looks at the actual data from IT systems and deduces how processes actually run. This eliminates subjective distortions – you get an objective picture instead of an idealized model. Put simply, classic analysis asks people “How should the process run?”, while process mining asks the systems “How did the process run?”.

What data is needed for process mining?

Process mining is based on event data (event logs) from the IT systems in which processes run. These logs should contain three essential pieces of information for each transaction: a unique transaction ID (e.g., order number), an activity name (which step was performed), and a timestamp. Often, operational applications such as ERP, CRM, or ticketing systems already provide exactly this type of data. In addition, attributes such as users, cost centers, or material numbers can be useful for analyzing the process from different angles later on. It is important that the data is complete and accurate – the more relevant events are recorded, the more detailed and meaningful the process picture will be.

How do you start a process mining project?

It is best to start on a small scale. First, select a process that is important and provides sufficient digital data (such as the invoice approval process or order processing). Then obtain the relevant event data from the IT systems. It is worth involving IT and the specialist department at an early stage. In a pilot project, a suitable process mining tool is applied to this data. The initial analyses quickly deliver tangible results that can be discussed with process owners. Based on these experiences, the project can be expanded step by step: examine further processes, connect more data sources, and get employees on board through training. In short: start small, learn quickly, and scale with a plan – this is how to make the introduction of process mining a success.

What role does artificial intelligence play in process mining?

Artificial intelligence (AI) is increasingly finding its way into process mining, but it is not a must. Classic process mining algorithms do not require machine learning – they follow fixed rules to reconstruct processes from logs. However, more and more providers are adding AI functions to their tools: for example, prediction models that forecast when a current case is likely to be completed, or anomaly detection that automatically reports unusual events. Such process AI features can extend the benefits by proactively pointing out problems or suggesting optimization potential. However, process mining remains a valuable tool even without AI.

Conclusion

Process mining has evolved from an academic concept to a key technology for digital process management. The method provides companies with a clear benefit: it transforms data traces into tangible insights that can be used to make processes more efficient, faster, and more robust. In light of increasingly complex processes and growing data volumes, process mining will continue to gain importance in the future. In combination with real-time monitoring and AI support, it is likely to become an indispensable component of modern organizational management. Companies that embrace process mining early on lay the foundation for a data-driven culture of continuous improvement – and thus for sustainable success in the digital age.

About our Expert

Mario Bock

AI Application Specialist | Corporate Marketing

Mario Bock has been working in Corporate Marketing at INFORM as an AI Application Specialist since 2023. He joined INFORM in 2016 and began his career in software development. Driven by his enthusiasm for artificial intelligence, he authored a book about the fundamentals of AI and now focuses on applying AI tools within marketing. With a passion for innovation and practical AI use cases, he helps shape the future of communication and content creation at INFORM.