Nov 24, 2025 Zdravka Ley

ShareIntralogistics is currently at a turning point. What was considered innovative just ten years ago - testing automated guided vehicles (AGVs) and using them in designated areas of factories - has now become standard practice in many plants. However, the once clearly defined pilot zones have evolved into a complex coexistence: forklifts, tugger trains, and AGVs operate side by side, managed by different control systems, separate data sources, and incompatible interfaces.

The result is fragmented material flows, a lack of transparency, inefficient workflows, and rising process costs. These system silos prevent modern technologies from unfolding their full potential. Today, those aiming to boost efficiency should not focus primarily on further automation, but rather on smarter integration and connectivity.

The dilemma of isolated solutions

In many production environments, different type of transport vehicles operate next to each other, but not with each other. Forklifts, tugger trains, and AGVs are each managed by their own control systems, exchanging only limited information.

This leads to disconnected workflows. An AGV system may know which routes are occupied, but not that a tugger train is entering the same area. A forklift driver deliver a pallet to a buffer zone but has no visibility into whether the staging area is already full, since the AGVs responsible for pickup do not communicate back to the forklift system.

The consequences are duplicated movements, waiting times, and inefficient use of resources. And especially in multi-stage transport chains, such as from warehouse to transfer point to assembly line, these system boundaries add up to significant efficiency losses.

This problem is not new. Back in the 1980s, many plants faced a similar challenge when the first digital forklift control systems were introduced. Individual halls or areas were optimized in isolation, but without transparency across the entire material flow.

Today, isolated control may still yield local efficiency gains, but it can no longer unlock the full potential of a connected intralogistics ecosystem.

The key lies in integration

This means that all transport orders, resources, and routes are brought together in a single central system. Only then does a unfied data foundation emerge, one that creates transparency across the entire material flow.

The key is in the coordinated control of hybrid fleets consisting of a wide variety of resources, from forklifts to AGVs. Standards such as the VDA 5050 interface provide an important foundation for data exchange between fleet management systems and automated guided vehicles from different manufacturers.

This is exactly where INFORM's SYNCROTESS transport management system comes into play. The software unifies all vehicles - from forklifts and tugger trains, and AGVs - in one central control system. It bundles all transport orders, analyzes priorities, capacities, and constraints, and determines within seconds which resource can handle each order most efficiently. If necessary, the system automatically breaks transports into multiple stages, for example, when a tugger train collects material from the warehouse, a forklift handles repositioning, and an AGV complets the final leg to production.

The result is a continuous, intelligent material flow without system breaks.

How much potential lies in a hybrid control approach?

A hybrid control system ensures that each type of vehicle can play to its strengths: the tugger train on longer, predefined routes, the forklift truck for flexible tasks, and the AGV for highly standardized and plannable transports.

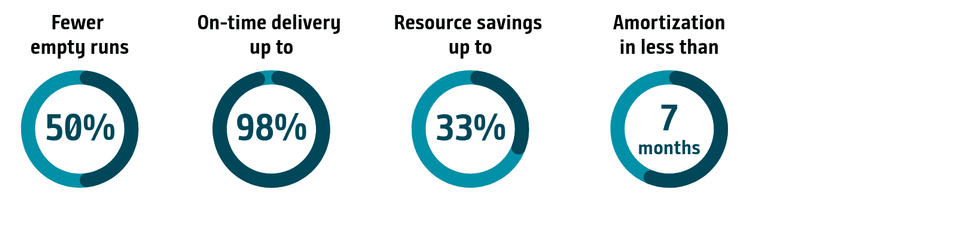

The central system always has complete visibility into all orders, vehicle positions, and available resources. It evaluates priorities and distances, compares capacities, and automatically assigns the resource that can execute the task most efficiently. This leads to optimally distributed transports, fewer empty runs, and early detection of potential bottlenecks. Companies achieve delivery reliability of up to 98 percent and resource savings of up to 33 percent.

A practical example from the automotive industry shows how this works:

In body shop operations, the SYNCROTESS transport control system manages all internal transport operations, from forklifts and tugger trains to AGVs.

Automated production equipment such as welding or bounding machines must be supplied continuously with components. The machines automatically report their material requirements to SYNCROTESS, which selects the appropriate resource in real time and distributes the orders efficiently. A forklift brings new material from the warehouse and places it to a defined transfer point. In the next step, SYNCROTESS assigns two AGVs to continue the process. One delivers the material to the machine, while the other returns the empty container to the warehouse.

This ensures uninterrupted machine operation and a smooth, reliable material flow. Multi-stage transport chains are intelligently orchestrated with significantly fewer empty runs, more stable processes, and higher supply reliability.

Conclusion: Integration is the key to the future of intralogistics

The intralogistics of the future will no longer be defined by individual vehicle types, but by connected, end-to-end processes. Only when all transport ressources are planned and managed together can the full potential of both automated and manual equipment be realized. Hybrid control systems create decisive added value by combining transparency, efficiency, and flexibility into one continuous material flow.

Instead of isolated point solutions, companies gain an intelligent overall system that reacts dynamically to changing conditions, utilizes resources optimally, and prevents unnecessary downtime. Those who pursue this level of integration today are laying the foundation for scalable, resilient, and future-proof factory logistics.

How well are your transport processes connectes today, and where do breaks in your material flow still occur?

About our Expert

Zdravka Ley

Marketing Manager

Zdravka Ley started working for INFORM in 2002 and is focused in topics around the optimization and sustainability of delivery and internal transport logistics.