ARaymond

Success Story

An overview of the entire S&OP process

When are which items in demand? How can demand be met cost-effectively? When does the production of articles have to start? Automotive supplier ARaymond answers these key questions with the help of the intelligent ADD*ONE solution suite. The INFORM software integrates sales, inventory, and production planning in a transparent system. And it does so for a portfolio comprising 25,000 items that need to be planned efficiently across all production stages. The result is the optimization of the entire value chain – from sales and procurement to planning work processes in production – in a single system. This is also the basis for an effective S&OP process.

ADD*ONE forms the essential data basis for our now-established S&OP process, all from one system. This has not only allowed us to greatly simplify the process, it is also based on a valid foundation and is therefore more efficient.

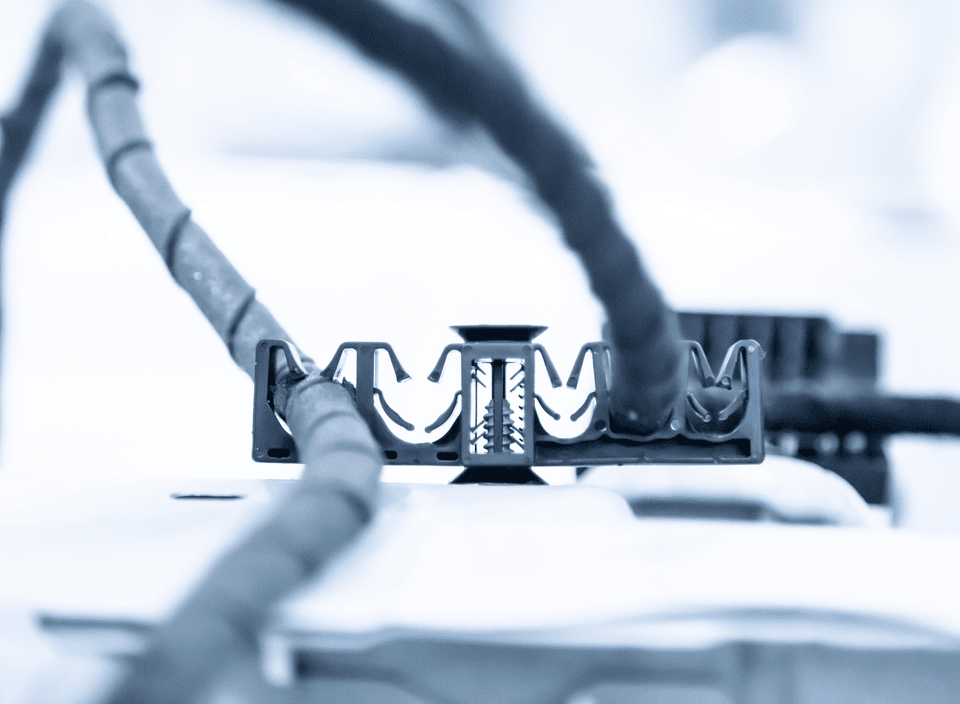

With 1,441 employees, A. Raymond GmbH & Co KG, the largest company in the A. Raymond network, is based in Lörrach and produces over 25,000 different items for the automotive industry. Their challenges for supply chain management are complex. There are 48,000 article-customer combinations for the product portfolio, and the production volume of five billion finished parts per year requires the precise planning of 13,000 resources – including hundreds of machines and thousands of tools. This results in a large number of possible combinations in production to meet market demand. "Our extensive product range and diverse production processes require a digital planning method that allows us to optimize the entire value chain transparently," explains Julian Keller, Team Lead Supply Chain at A. Raymond.

Previously, the complex planning was carried out using the ERP system and extensive Excel lists. "However, the articles we produce are extremely dynamic in terms of customer orders, with a particularly high number of sporadic article call-offs," Keller continues. "This requires the ability to react quickly in order to be able to adapt the planning to corresponding changes at short notice." Using only conventional planning methods, A. Raymond reached its limits.

The ADD*ONE solution suite, which specializes in optimizing the entire value chain, proved to be the most comprehensive and suitable solution for A. Raymond in the search for a suitable system. In addition, INFORM's experts quickly developed a deep understanding of the automotive supplier's specific processes. "We have maintained a close and cooperative partnership from the start of the project to the present day," says Keller. Keller was also impressed by the scope of the INFORM software. Algorithms specially developed for sales planning provide reliable sales forecasts throughout the company on a daily basis. "Sales, production, procurement management and management use this basic information from ADD*ONE and supplement the planning with their specialist knowledge. The software then provides us with a coordinated plan that is comprehensible for all departments," says Keller. "The planners can now flexibly link and plan each individual item with all levels such as customer, region and product group.

Read the full success story for more details on the project and its successes.

CHALLENGES

RESULTS