Nov 24, 2025 // Zdravka Ley

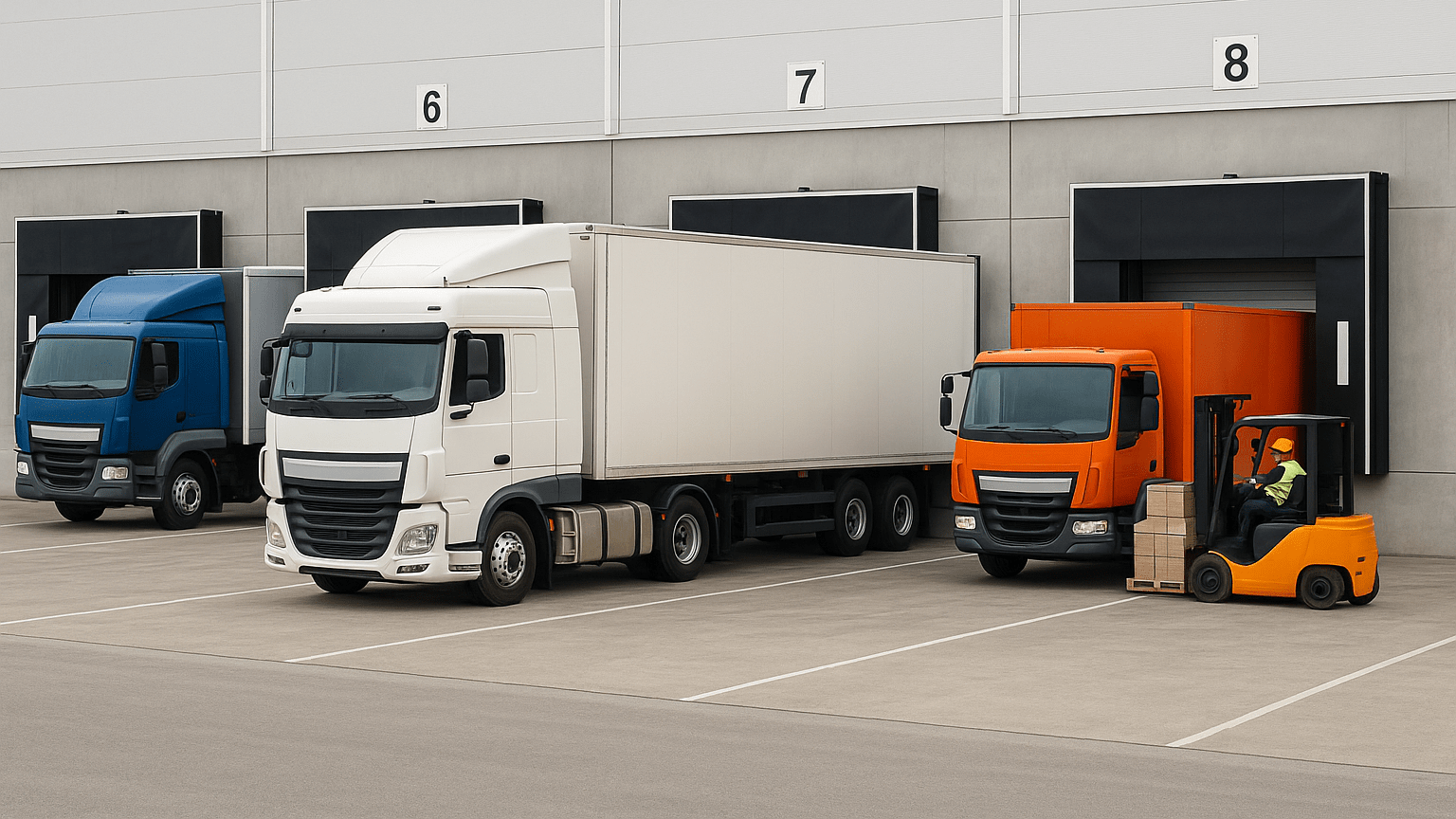

From isolated solutions to integrated material flow

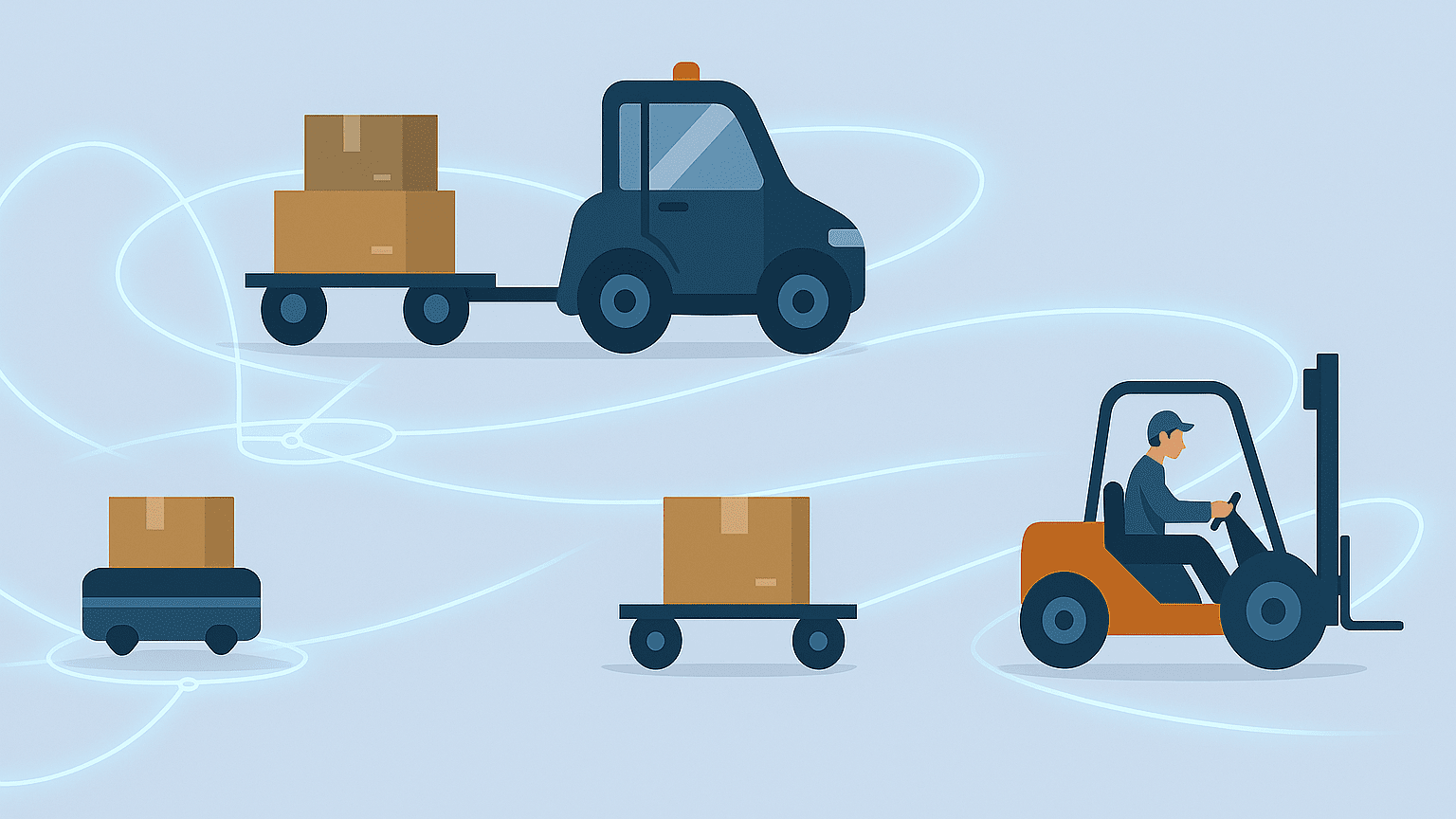

Many plants still rely on separate control systems for forklifts, tugger trains, and AGVs - resulting in disconnected data, inefficiencies, and unnecessary costs. With hybrid fleet control, SYNCROTESS unifies all transport resources in a single system to enable seamless, intelligent material flow.