Jul 1, 2025 // Zdravka Ley

Pre-self check-in: how modern yard logistics begins

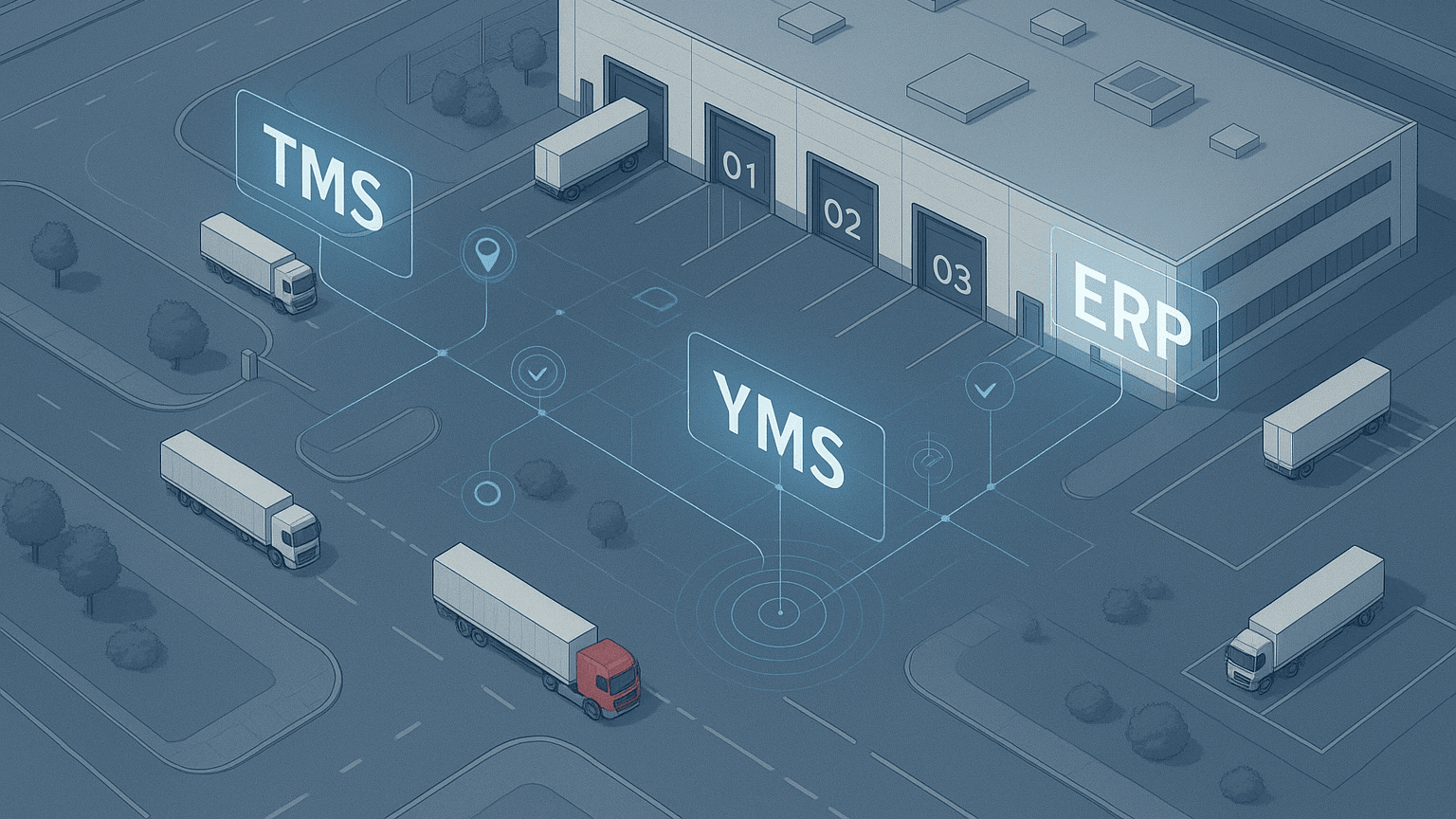

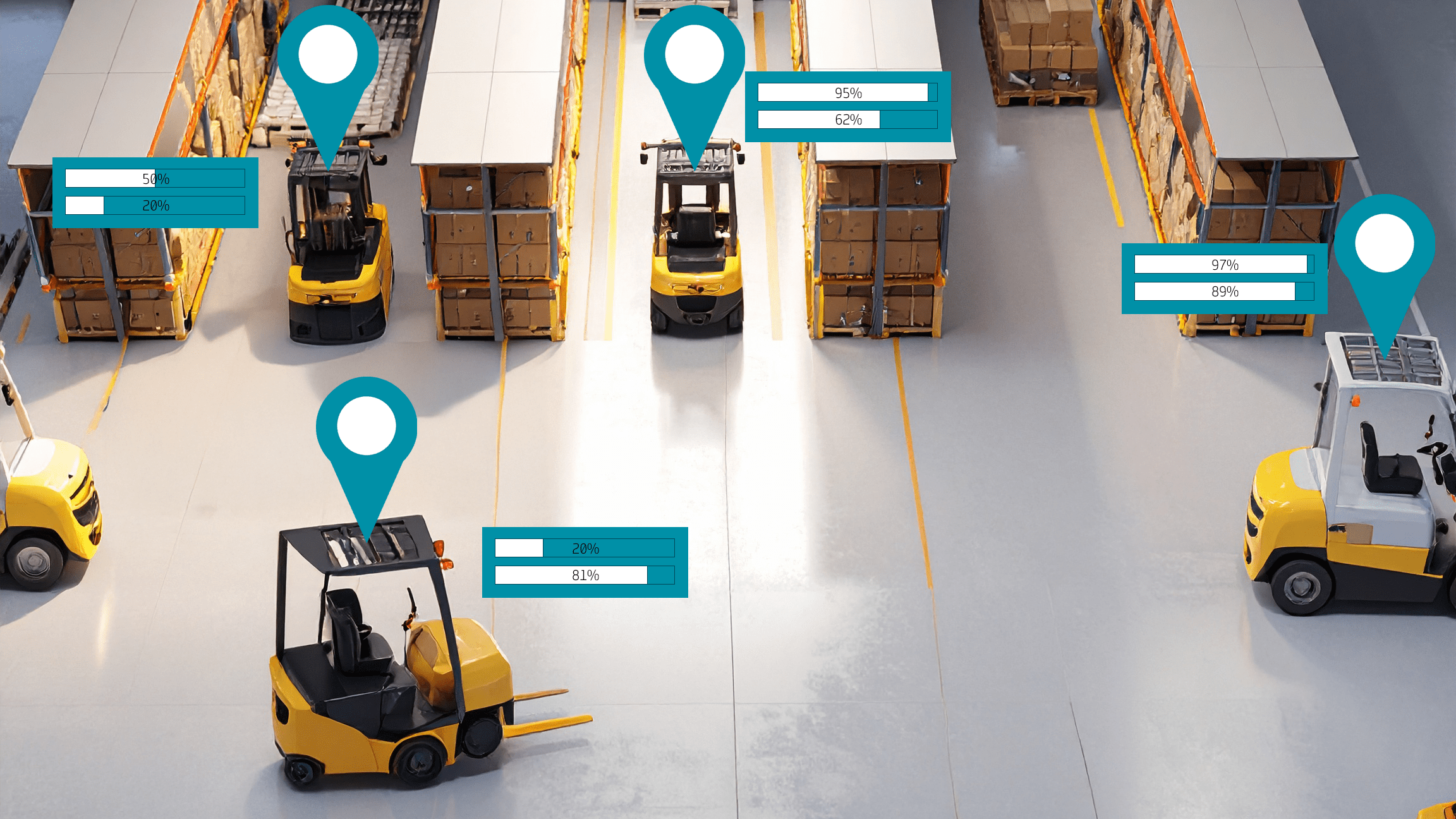

Pre-Self Check-In is an integral part of the SYNCROSUPPLY yard management software. The system enables location-specific regulations to be transmitted in advance and queries all relevant information about the vehicle and driver.