In many plants, Automated Guided Vehicles (AGVs), tugger trains, and forklifts are still planned and controlled separately. Each system operates with its own rules, data, and priorities – a shared decision-making basis is missing.

The result: empty runs, waiting times, and inefficient processes that slow down the entire material flow.

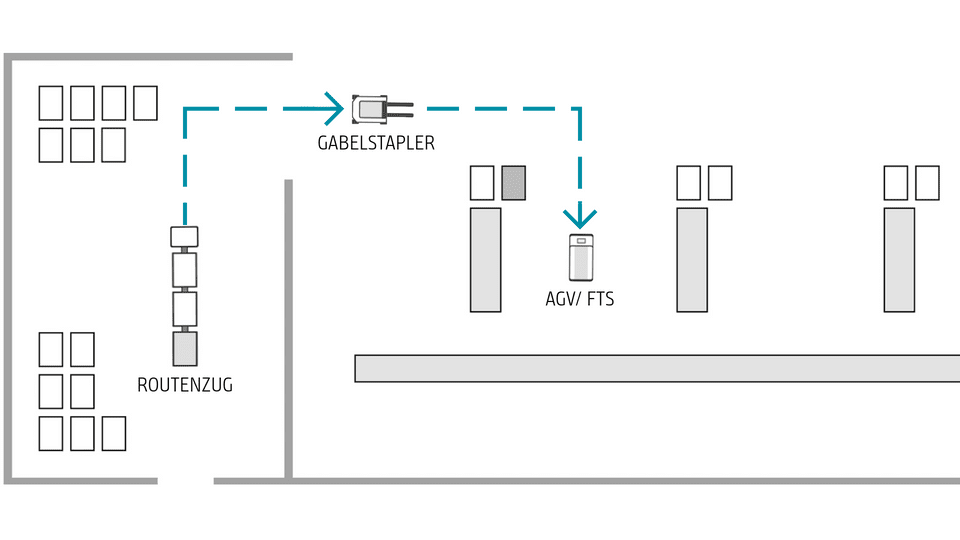

SYNCROTESS consolidates all transport orders within a central control system and decides within seconds which vehicle can execute each order most efficiently. Based on boundary conditions and vehicle characteristics, the system can automatically split transports into multiple segments when required – for example from a tugger train to a forklift and then to an AGV.

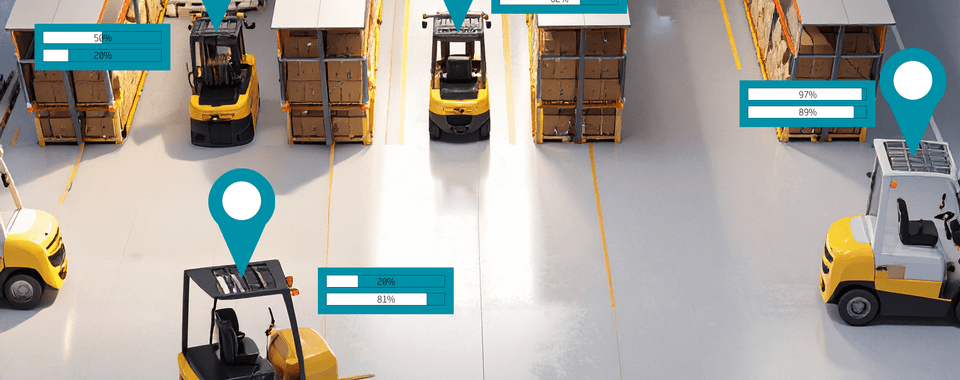

Real-time data from ERP, MES, and WMS systems, combined with vehicle status, order priorities, and traffic rules, continuously feed into the planning process. This enables optimized transport routes, maximum resource utilization, and processes that adapt flexibly to changing conditions.

The result: end-to-end transparency, dynamic operations, and a seamless material flow.