Success Factor Demand Planning: More Sales. Less Effort.

INFOPAPER | 5 practical tips on how you can easily support your sales planners and plan your sales.

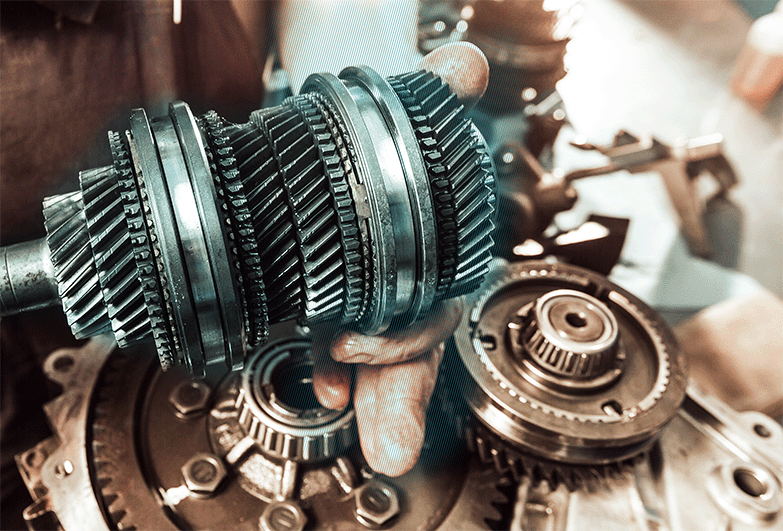

Turn Your After-sales Service into a Competitive Advantage

After-sales managers today face numerous challenges: Products often require many spare parts, which must be available in time to avoid downtime despite increasingly complex supply chains and fluctuating demand. At the same time, customer satisfaction always comes first.

Accordingly, it is important to manage and plan spare parts inventories with foresight. The decision-intelligent ADD*ONE solution suite helps you master these tasks and ensure that the parts you need are procured under cost-optimal conditions and reach your customers on time. With ADD*ONE, you optimize your spare parts business sustainably and turn your after-sales service into a real competitive advantage!

Maximum Delivery Capability and Optimum Inventories

As add-on software, the ADD*ONE solution suite overcomes the classic limitations of your ERP system. The software supports you in managing, controlling, and sustainably improving the spare parts management in your company through AI-supported, powerful forecasts and algorithms. With ADD*ONE, you regain full transparency over your inventories' overall situation and disposition tasks.

More Planning Reliability

Recognize demands for spare parts, even when they seem to "fall from the sky." Items with highly fluctuating demand are a challenge for conventional analyses. ADD*ONE considers products' life cycles and enables qualified planning to control and manage even these sporadic demands. In this way, you optimize your spare parts supply and ensure your ability to deliver!

Save Time and Resources

The optimization software can be integrated almost seamlessly into your existing IT infrastructure. With minimal effort, you can put ADD*ONE into operation and benefit from the advantages of efficient spare parts planning. The smooth implementation of ADD*ONE saves you time and reduces the need for additional resources. This allows you to concentrate on your core processes while optimally planning and controlling your spare parts supply.

ADD*ONE frees us up to focus on the real challenges in our procurement. The interaction of artificial intelligence for the standard cases and human intelligence for the special cases is proving to be a complete success.

Christoph Wiericks

Expert for Supply Chain Optimization

Christoph Wiericks has been strengthening the Inventory & Supply Chain division at INFORM GmbH since 2016. With in-depth expertise in supply chain optimisation, he supports companies in selecting the right AI solutions. His particular focus is on analysing and optimising inventories and implementing efficient planning strategies. As an experienced sales specialist, he guides companies through the decision-making process and finds tailored solutions to their challenges.