Mechanical Engineering

FELIOS in use at

Oskar Frech

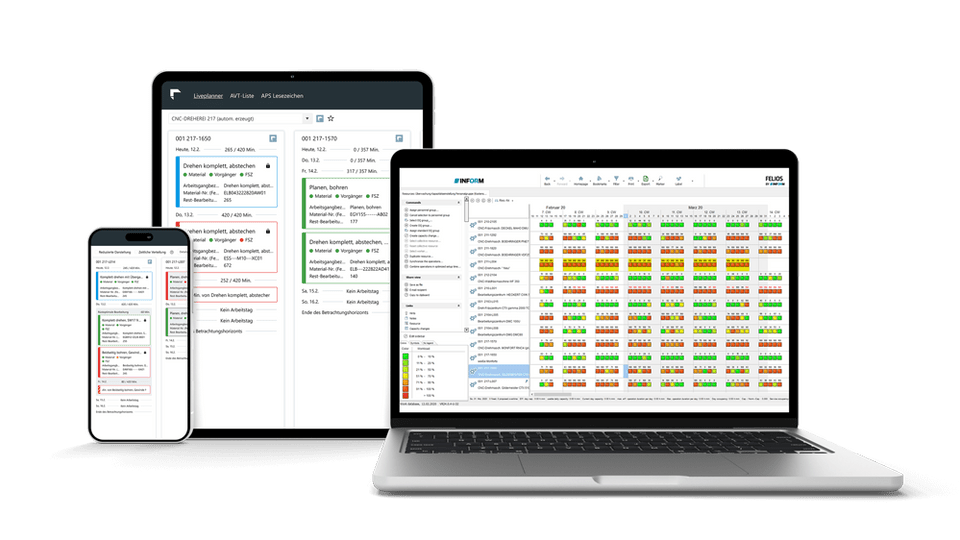

For Joachim Wörner of Oskar Frech, FELIOS is as powerful as a lion: In use since 2006, it reliably supports the company in meeting precise delivery deadlines. The company is currently driving forward assembly planning with FELIOS I PM.