Vehicle Yard Management

Download our brochure.

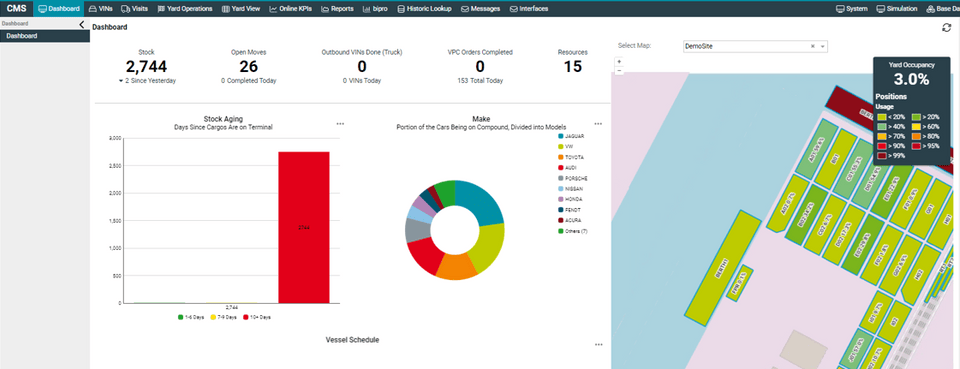

The complex processes at a car terminal require an intelligent system to efficiently manage your employees, the terminal and the vehicles.

Our software helps you stay on top of things and automate terminal operations.

Vehicle yard management refers to the coordination and control of vehicle storage and movements within dedicated facilities, where finished vehicles are temporarily stored before being transported to their final destination. Effective yard management is critical for ensuring the timely and safe delivery of vehicles, reducing delays, and optimizing space and resources.

With our specialized vehicle yard management software, automotive companies can efficiently plan, monitor, and streamline the complex operations involved in yard management. The solution helps optimize storage, minimize vehicle handling times, and improve overall logistics efficiency from the moment vehicles arrive at the yard until they leave for their final delivery.

VINCE is a collaboration platform for logistics service providers, OEMs and their partners and customers, enabling INFORM customers to provide their partners and customers with visibility into orders, logistics-related processes and vehicle details and movements.

Transforming Vehicle Logistics: Pivotal Role of IT and AI

This study presents a comprehensive analysis of the evolving landscape in vehicle logistics management, with a special focus on the impact and integration of information technology (IT).

Want to learn more about how our solutions work in the real world? Then you have come to the right place!