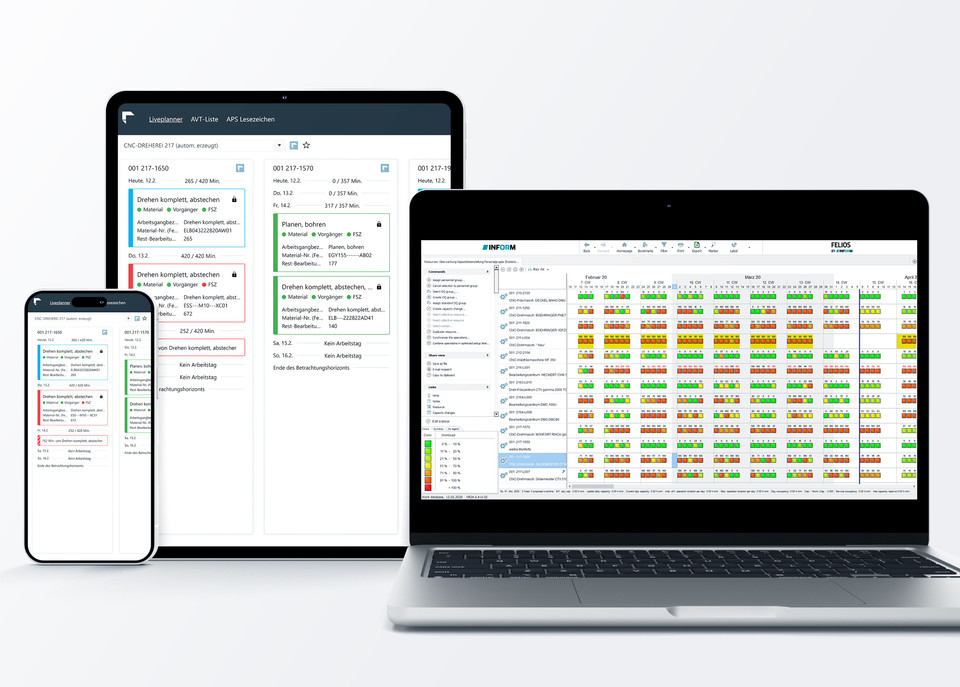

DEVELOPED WITH EXPERTISE AND IN COOPERATION WITH OUR CUSTOMERS

Many years of experience in the industry, direct exchanges with our customers, and continuous development – that is what distinguishes our solution from others. With FELIOS, you will be able to react realistically, reliably, and transparently to diverse challenges.

CONSULTING - FOCUSING ON PEOPLE

Our consultants and experts develop a concept that considers all your requirements and needs together with your team. We want to make sure, that you get the perfect solution for an easy integration into your daily working life.

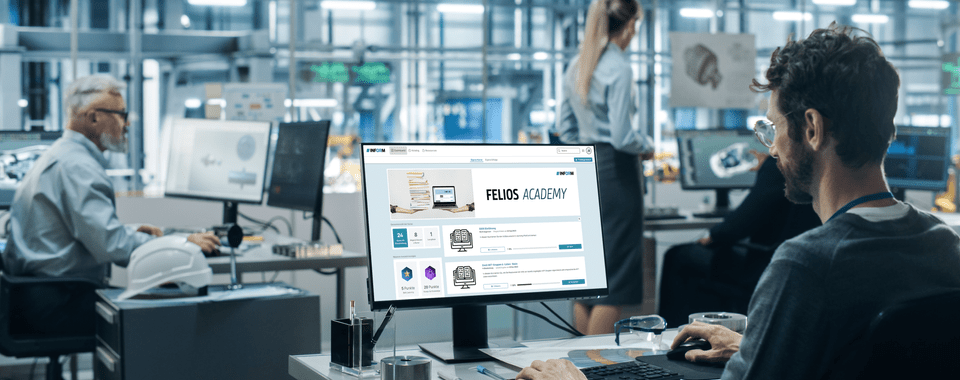

COACHING, TRAINING, AND SUPPORT FOR FURTHER DEVELOPMENT

We will not leave you alone after the launch! Our experts will accompany your team in their daily business with coaching, customization, and our support. Your personal contact will keep you informed about new features and optimizations.

EXCHANGE BETWEEN EXPERTS

We offer various events, where you will get the chance to join professional exchanges of FELIOS users.